Concrete Splitting or Hydraulic bursting

Offers the ability to fragment almost unlimited areas of concrete, either horizontally or vertically, with or without reinforcement.

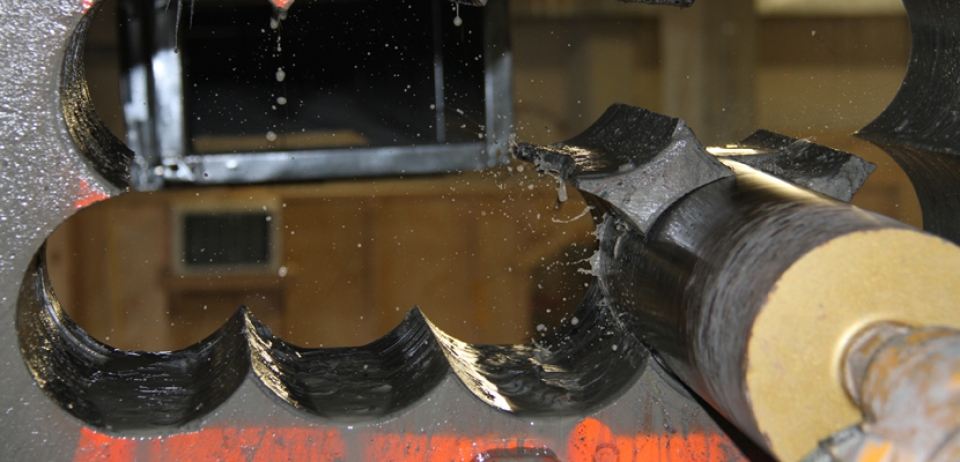

- The method involves drilling a matrix of holes approximately 350mm apart into the area to be demolished. Once the holes are drilled, the bursting piston equipment is inserted and the process begins.

- Hydraulic Bursting takes longer than hydraulic crunching due to the preparation of drilling the holes, but has similar advantages of low noise and low dust.

-

Benefits:

- Clean, quiet concrete demolition

- Suitable for reinforced concrete walls and floors

- No HAVS

- Our Company uses expanding grouts.

- Expanding grout is a non-explosive chemical cracking agent which enables controlled fragmentation to be carried out with comparative accuracy. This process is also virtually silent and creates no vibration or fly rock.

- Expanding grout is packed into a matrix of pre drilled holes in the material to be fragmentated.

- A reaction time of a few hours creates a cracking pressure of 4,000 tonnes per square metre, increasing to in excess of 5000 tonnes per square metre.

-

Benefits:

- Virtually silent concrete demolition

- Low dust

- Ideal for fragmentation of reinforced concrete, rock or stone

- By using some or all of the cutting and drilling techniques available to us, we are able to demolish all or part of buildings and structures without any damage to surrounding or adjoining buildings.

- Each project is unique and we have the expertise, knowledge and equipment to undertake complex demolition tasks.

- Our management team can advise as to the suitability of each particular technique to the proposed project.

-

Benefits:

- Controlled demolition

- Robotic demolition

- No HAVS

0418 863 739

0418 863 739